Focus on digitalization

1. Introduction

With the sweeping wave of digitalization, the industrial sector is rapidly moving toward greater intelligence and efficiency. As fundamental components of industrial automation, industrial sensors are embracing new opportunities and challenges in the digital era. They not only provide enterprises with accurate and reliable measurement data but, through deep integration with digital technologies, also enable intelligent production management and decision-making. This article explores the innovations and applications of industrial sensors in the digital age and highlights some successful case studies.

2. Innovations in Industrial Sensors in the Digital Era

(1) High Precision and Reliability

In digital manufacturing, the requirements for sensor accuracy and reliability are higher than ever. The new generation of industrial sensors leverages advanced sensing technologies and manufacturing processes to achieve highly precise measurements with excellent stability and reliability. For example, high-precision temperature sensors can accurately control process temperatures, ensuring consistent product quality.

(2) Intelligence and Self-Diagnosis

Smart sensors are equipped with data processing and analysis capabilities, allowing them to automatically diagnose their operational status and provide feedback to users. This makes sensor maintenance more convenient and reduces production interruptions caused by sensor failures. For instance, certain intelligent pressure sensors can continuously monitor pressure levels and issue alerts when anomalies occur, reminding users to perform timely maintenance.

(3) Wireless Transmission Technology

The emergence of wireless sensors has broken through the limitations of traditional wired systems, making installation and deployment more flexible and convenient. Using wireless transmission, sensors can transmit data in real time to central control systems, enabling remote monitoring and management. For example, in large-scale industrial equipment, wireless level sensors can be easily installed in hard-to-reach locations to monitor liquid levels in real time.

3. Successful Cases of Sensor-Digital Integration

(1) Smart Manufacturing

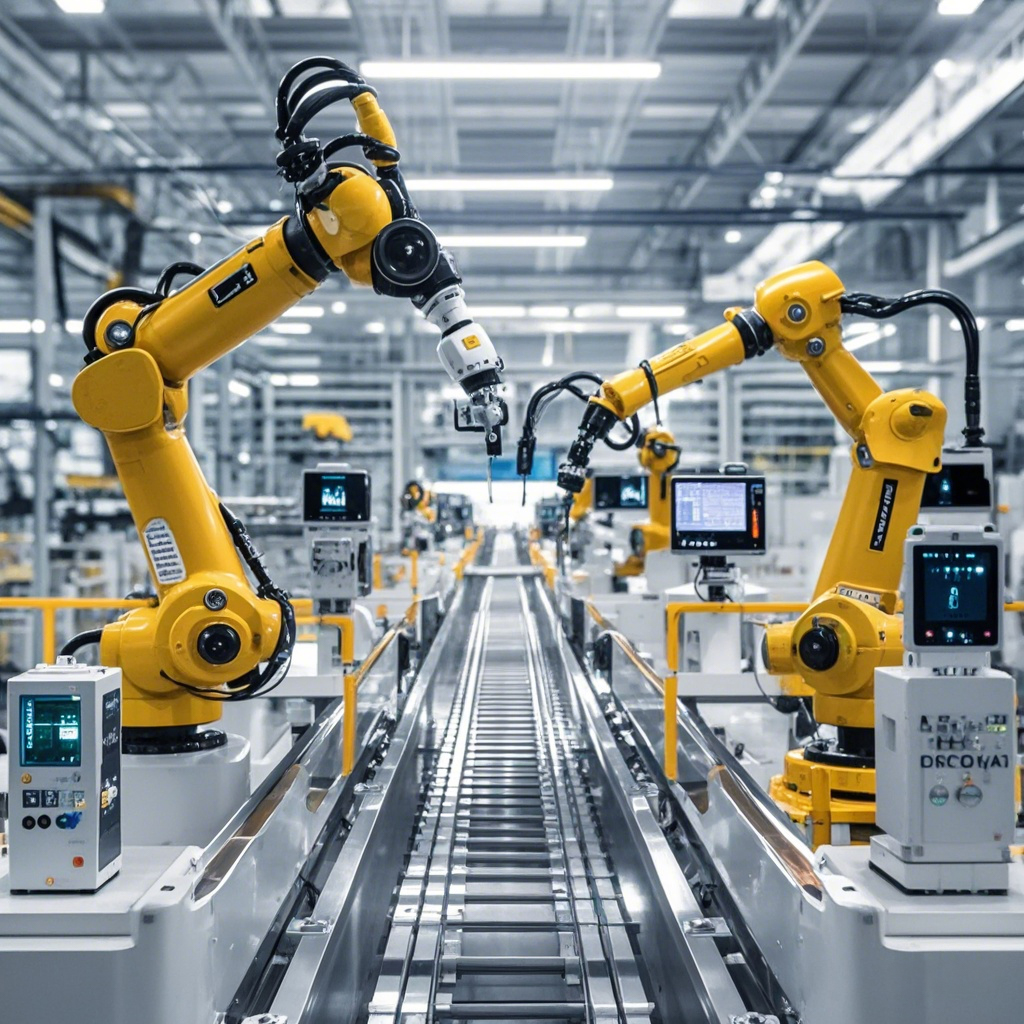

In smart manufacturing plants, the integration of industrial sensors with digital technologies has enabled highly automated and intelligent production processes. For example, by deploying temperature, pressure, and displacement sensors on production lines, enterprises can monitor key parameters in real time and automatically adjust processes via digital control systems to ensure product consistency. At the same time, digital systems can analyze production data to optimize workflows and improve efficiency. One smart manufacturing enterprise, through the adoption of advanced sensors and digital solutions, achieved unmanned management of its production processes, significantly enhancing its competitiveness.

In smart logistics systems, the integration of sensors and digital technologies enables real-time monitoring and management of logistics processes. For example, by installing temperature, humidity, and level sensors in warehouses, enterprises can continuously monitor storage conditions to ensure the safety of goods. At the same time, digital systems can analyze logistics data to optimize delivery routes and improve efficiency. One smart logistics company, by adopting advanced sensors and digital solutions, achieved visualized management of its logistics processes, reduced operational costs, and enhanced customer satisfaction.

IV. Challenges and Strategies of Industrial Sensors in Digital Transformation

(1) Data Security and Privacy Protection

With the continuous growth of sensor data, ensuring data security and privacy has become a major challenge for enterprises. Companies should strengthen data encryption and access control for sensor data to guarantee its safety and confidentiality. At the same time, governments and industry associations should establish relevant laws, regulations, and standards to regulate the use and management of sensor data.

(2) Technical Standards and Compatibility

Differences in technical standards and compatibility among sensors from different manufacturers create difficulties for enterprises in sensor selection and system integration. To address this issue, enterprises should choose sensor products that comply with international standards and industry specifications, while also strengthening cooperation with sensor manufacturers to jointly promote standardization and interoperability in sensor technologies.

(3) Talent Development and Technological Innovation

The integration of industrial sensors with digital technologies requires professionals with interdisciplinary knowledge. Enterprises should enhance talent training and recruitment to improve employees’ technical skills and innovation capabilities. At the same time, companies should increase investment in technological innovation, continuously introducing new sensor products and digital solutions to meet market demands.

V. Conclusion

The digital era presents both new opportunities and challenges for the development of industrial sensors. Through continuous innovation and application, industrial sensors will play an increasingly vital role in digital transformation. Enterprises should actively embrace the digital age, strengthen the application and management of industrial sensors, and improve production efficiency and product quality to achieve sustainable growth. Meanwhile, governments and industry associations should provide greater support and guidance to the industrial sensor sector, driving technological innovation and development.