Focus on digitalization

I. Introduction

In today’s highly competitive industrial sector, digital transformation has become crucial for the survival and growth of businesses. Industrial sensors, as a key element of digitalization, are deeply integrated with digital technologies through their powerful sensing capabilities and data transmission functions, collectively driving industrial change. This article will explore the close connection between industrial sensors and digitalization, highlight their important roles in the industrial field, and share some successful case studies.

II. Industrial Sensors: The Perceptual Foundation of Digitalization

(I) Accurate Data Collection

Industrial sensors can precisely measure and monitor various physical quantities such as temperature, pressure, and liquid level. Whether in harsh environments with extreme temperatures and pressures or in precision settings where even minor changes matter, sensors can accurately capture data. For instance, high-precision temperature sensors can monitor the temperature of industrial furnaces in real-time, ensuring that the temperature control during the production process stays within a precise range.

(II) Real-Time Data Transmission

Modern industrial sensors typically feature digital output capabilities, allowing the collected data to be transmitted in real-time to central control systems or cloud servers. Through high-speed data transmission channels, businesses can stay updated on the production site conditions, providing the latest information to support decision-making. For example, wireless liquid level sensors can transmit liquid level data in real-time to the monitoring center, allowing staff to always be aware of the tank's liquid level status.

(III) Multi-Parameter Monitoring

Industrial sensors can simultaneously monitor multiple parameters, providing businesses with comprehensive production status information. For instance, intelligent monitoring devices that integrate temperature, pressure, and humidity sensors can offer a complete monitoring solution for the industrial environment, helping companies detect potential issues in a timely manner.

III. Digitalization: Uncovering the Value of Sensor Data

(I) Data Analysis and Processing

Digital technologies provide powerful tools for the analysis and processing of sensor data. With big data analysis, artificial intelligence, and machine learning, businesses can extract valuable insights from vast amounts of sensor data, discovering underlying patterns and trends. For example, by analyzing pressure sensor data over time, companies can predict equipment failure cycles and perform maintenance in advance.

(II) Intelligent Decision Support

Based on digital analysis results, businesses can make more scientific and accurate decisions. For instance, by analyzing data from temperature and liquid level sensors, companies can optimize production process parameters to improve product quality and production efficiency. Digital systems also provide real-time decision support, helping businesses respond quickly to unexpected situations.

(III) Remote Monitoring and Management

Digital technologies enable companies to monitor and manage industrial production processes remotely. Using the internet and mobile devices, business managers can check sensor data anytime and anywhere, staying informed about production site conditions. This not only improves management efficiency but also reduces operational costs for businesses.

IV. Successful Case Studies of Sensor and Digitalization Integration

(I) Smart Warehouse Management

In the smart warehouse system of a large logistics company, temperature, humidity, and pressure sensors are widely used to monitor the warehouse environment. The sensors transmit the collected data in real-time to a digital management platform, which automatically adjusts the warehouse’s ventilation, refrigeration, and heating systems through data analysis to ensure that goods are stored in optimal conditions. Additionally, with liquid level and weight sensors installed on the shelves, the company can track inventory in real-time, achieving precise inventory management.

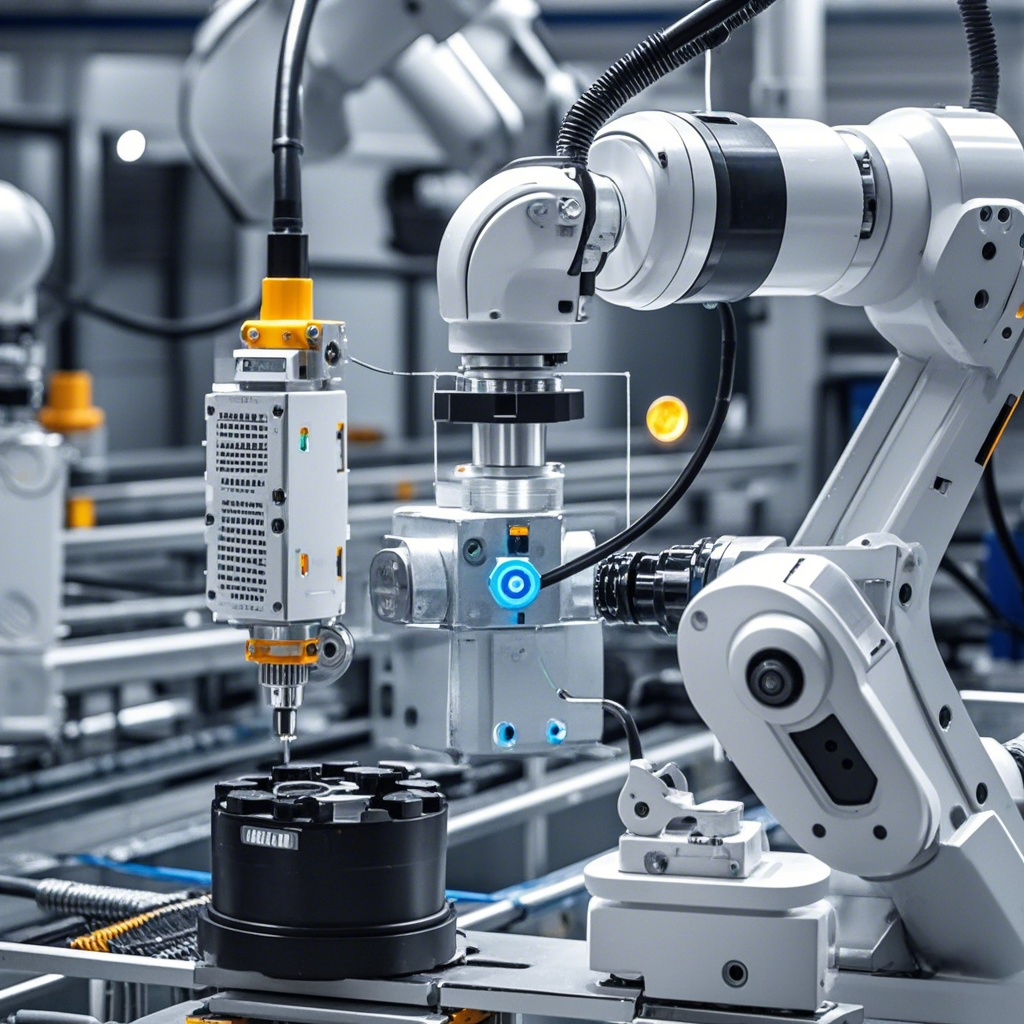

In the field of industrial robotics, the integration of sensors and digital technologies has made robots more intelligent and flexible. For example, force sensors and displacement sensors installed on the robot's arm can real-time detect the interaction forces and positional relationships between the robot and the workpiece. Through a digital control system, precise gripping and operation can be achieved. Additionally, by analyzing sensor data, robots can automatically adjust their working parameters to adapt to different production tasks.

V. Challenges and Response Strategies

(I) Data Quality Issues

Sensors may be affected by noise, interference, and other factors during data collection, leading to a decline in data quality. To address this issue, businesses can use data filtering, calibration, and validation techniques to improve the accuracy and reliability of sensor data. Additionally, strengthening sensor maintenance and management, including regular calibration and inspections, will help ensure stable sensor performance.

(II) Data Security and Privacy Protection

With the continuous increase in sensor data, data security and privacy protection have become critical challenges for businesses. Companies should implement measures such as encryption, access control, and data backups to ensure the security of sensor data. Furthermore, it is essential to strengthen employee awareness of data security through training, establish strict data management regulations, and prevent data breaches.

(III) Technological Integration and Innovation

The integration of industrial sensors and digital technologies requires constant innovation and exploration. Enterprises should increase investment in research and development, cultivate interdisciplinary technical talent, and promote the innovative development of sensor and digital technologies. Additionally, strengthening cooperation with universities, research institutions, and industry partners will help tackle technological challenges and drive the digital transformation of the industrial sector.

VI. Conclusion

The integration of industrial sensors and digitalization is an inevitable trend in the development of the industrial sector. Through precise data collection, efficient data transmission, and in-depth data analysis, sensors and digital technologies collectively provide robust support for industrial enterprises, driving the intelligence, efficiency, and sustainability of industrial production. In future development, businesses should fully recognize the importance of industrial sensors and digitalization, actively address challenges, increase investments, and continuously innovate to achieve transformation, upgrading, and sustainable development.